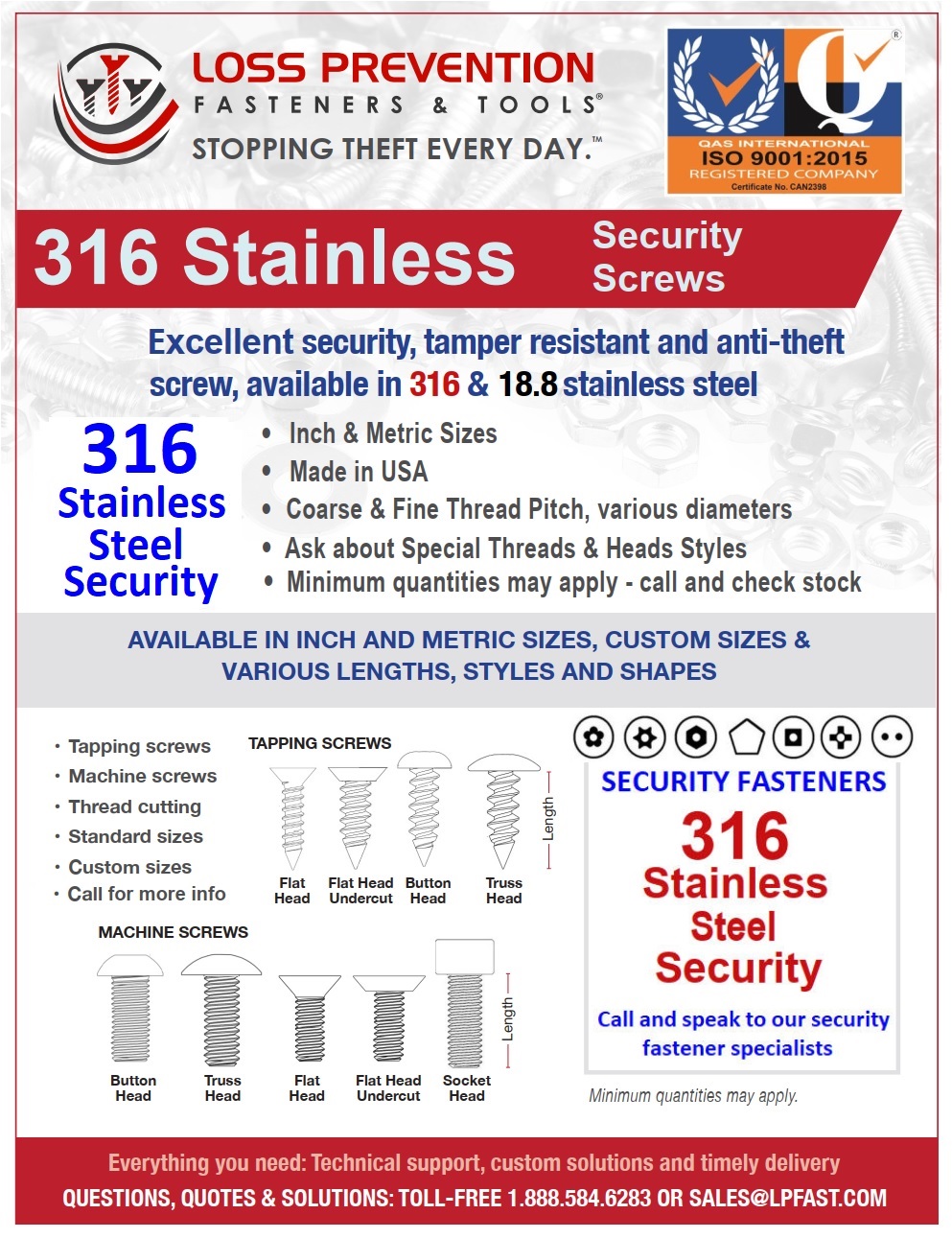

Stopping Theft Every day TM

316 Stainless Steel Security Fasteners

316 Stainless Steel Tamper Proof

316 Stainless Steel Security Fasteners available at Loss Prevention Fasteners

316 Stainless Steel Security

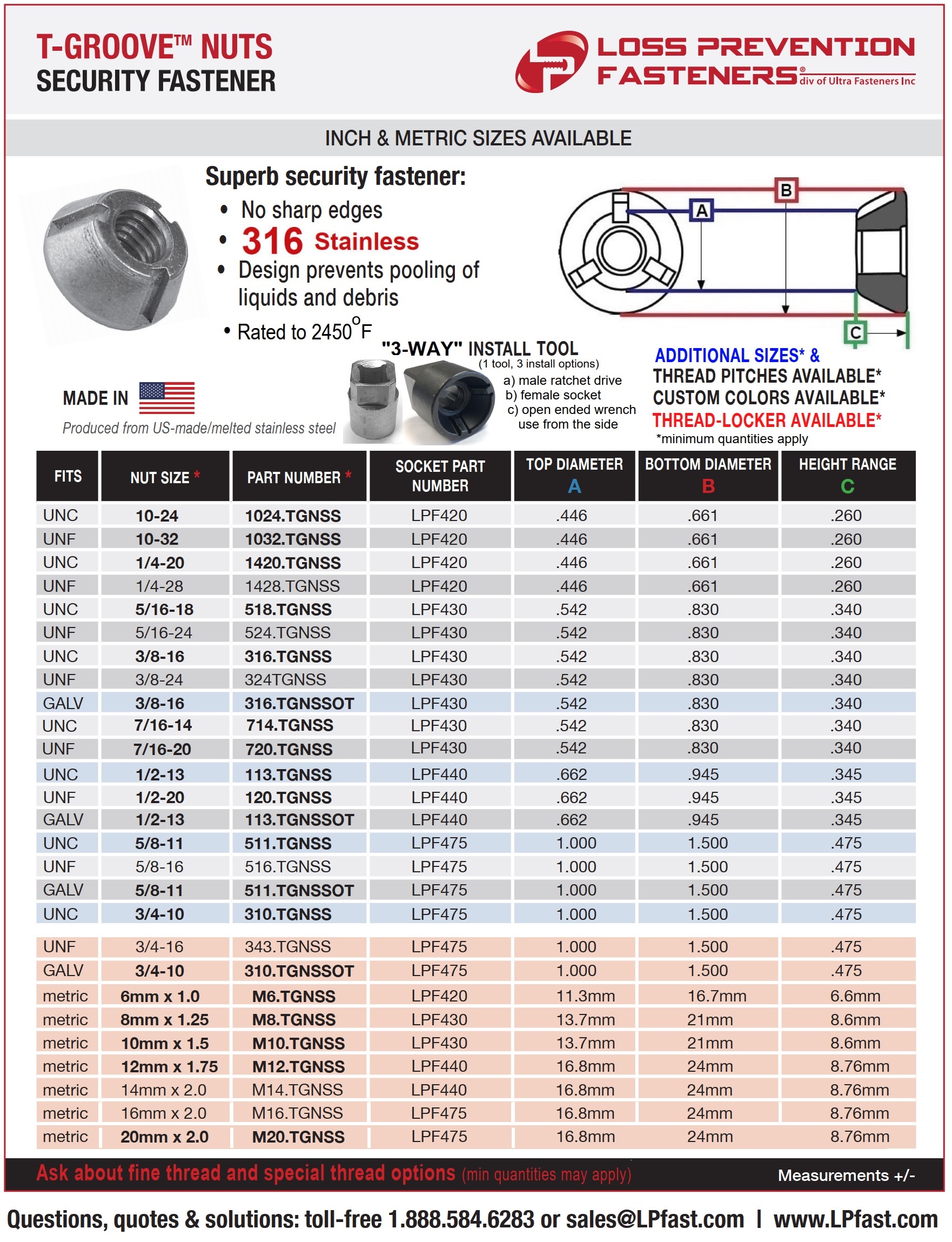

inch and metric Sizes

STAINLESS STEEL(not too)

TECHNICAL DATA

There are many different types of stainless. Stainless steel tamper proof is commonly referred to as 18.8 stainless or 316 stainless. The term ‘300 series’ typically refers to stainless steel security screws, nuts & bolts that are not made of “316 stainless steel”.

The Stainless Steel 300 series designation contains many different compositions of alloy steel (303, 304, 305, 316, 321, 347, etc.) but the common factors among them are:

- Their carbon content is generally held to a maximum of 0.08%

- They (generally) have 18% chromium

- They (generally) have 8% nickel

- They are non-magnetic or slightly magnetic

- They cannot be hardened by heat treatment

- They can be hardened by cold working the material (“work hardening.”)

While all 300 series stainless steel security fasteners share this 18/8 mix, slight differences in chemical composition between the different grades of the 300 series do make certain grades more resistant than others against particular types of corrosion.

In the fastener industry the term “18-8″ is often used as a designation for a security screw, ant-theftbolt, tamper resistant nut, or washer manufactured from 300 series stainless steel material that has the 18% chromium/8% nickel alloy mixture. Type 304 is by far the most popular of the 300 series stainless steels. NOTE: a fastener manufactured from stainless material that meets the 18/8 alloy mix does not necessarily meet the other slight differences in chemistry required to certify it as Type 304 stainless.

The second most popular type of stainless, after Type 304, is Type 316.

In 316 stainless the chromium content is lowered from 18% to 16%, however, the nickel content is raised to 10% and 2% molybdenum is added to the mixture. This change in the chromium/nickel ratio and the addition of the molybdenum increases the resistance to chlorides. This is why Type 316 stainless security fasteners is often used in more corrosive environments where the material will be exposed to chemical, solvent, or salt water corrosion and makes it the preferred material for marine construction.

Request a quote for your project

get pricing, tech support, or ask a question about our products